Consulting and Engineering Services

For the development, improvement and optimization of products and manufacturing processes, ModelWorks uses modern CAD, CAE and CAM computer simulation tools.

Design with CAD

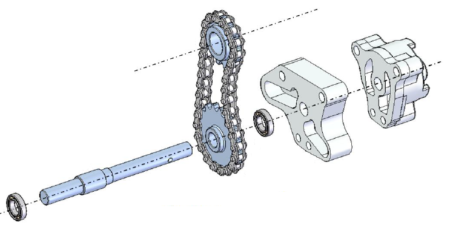

Computer-aided design tools, or CAD, are the basis for the development of any current engineering project. The CAD enables 3D detailed drawing in virtual environment of all the pieces that make up the project to be developed and assembled, ensuring their correct operation and avoiding mounting errors and incompatibilities between the pieces.

The professional CAD designer must keep in mind all the constructive requirements of each component and take into account the manufacturing processes and materials to be used, always seeking the simplification and project cost reduction.

The CAD drawing is also the starting point for analyzes in computer aided engineering tools, or CAE, and computer aided manufacturing, or CAM.

Finite Element Analysis (FEA)

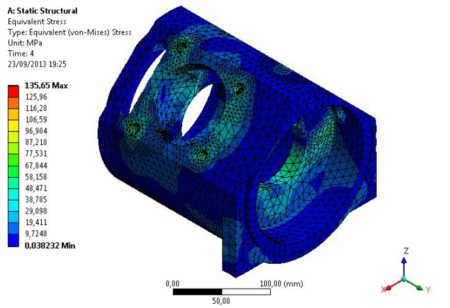

A widely used CAE tool is the structural analysis using the finite element method, or FEA (Finite Element Analysis), which is very useful for calculation of mechanical strength in complex parts. Through FEA simulations it is possible to predict the distribution of tensions along the entire geometry and to correct possible weaknesses even before the part is built.

A widely used CAE tool is the structural analysis using the finite element method, or FEA (Finite Element Analysis), which is very useful for calculation of mechanical strength in complex parts. Through FEA simulations it is possible to predict the distribution of tensions along the entire geometry and to correct possible weaknesses even before the part is built.

Computational Fluid Dynamics (CFD)

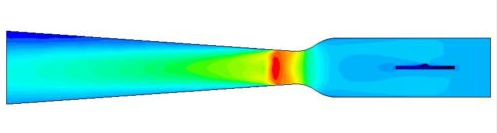

Another CAE tool of great utility in engineering projects is the computational fluid dynamics (CFD) simulation, through which it is possible to analyze virtually the characteristics of the flow of any fluid (air, water, oil, etc.) , allowing the calculation of pressure losses, velocity, pressure and temperature profiles, heat exchanges, among other parameters. External flow simulations also allow the calculation of lift, drag and downforce in aerodynamic, vehicular, and aeronautical aerodynamics analyzes.

Computerized Manufacturing (CAM)

After going through the CAD and CAE stages, the project reaches the manufacturing phase and assembly of the pieces for demonstration prototypes, validation prototypes and/or the final product. As a manufacturing aid, CAM tools can be used if computerized numerical control (CNC) machines are used to machine the parts.

After going through the CAD and CAE stages, the project reaches the manufacturing phase and assembly of the pieces for demonstration prototypes, validation prototypes and/or the final product. As a manufacturing aid, CAM tools can be used if computerized numerical control (CNC) machines are used to machine the parts.

The CAM software allows the generation of the G codes, which consist of the programming of all the operations to be carried out automatically by the CNC machines, allowing the machining time optimization and the precise generation of complex geometries.