3D Printing Services

3D printing is a kind of additive manufacturing that is gaining more and more space in professional applications. Similar to CNC machines, the G code programming for 3D printers is based on the 3D CAD drawing of the part to be manufactured.

The most common type of 3D printing is FDM (Fused Deposition Modeling), which performs printing by melting and depositing plastic materials.

The quality and precision of this type of 3D printing depends a lot on the G code setup and programming parameters, the main ones being the melting temperature of the material, the advance speed of the head, the thickness of the deposited layers, and the filling density of the piece.

Some care must be taken in defining the position in which the piece will be printed, in choosing the layers deposition direction and in the placement or not of supports, in order to avoid distortions of the geometry and surface finish. In this type of printing it is possible to achieve tolerances in the order of 0.1 mm, depending on the size of the piece.

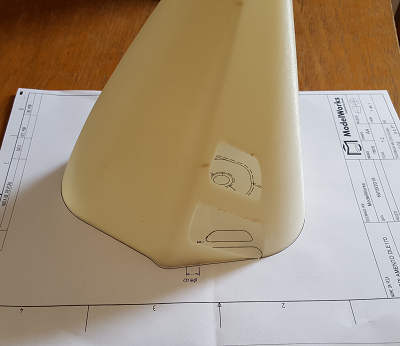

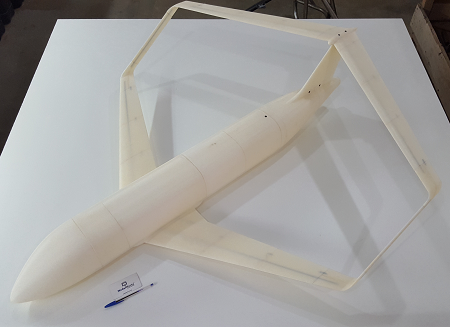

Large Format 3D Printing

The know-how acquired by ModelWorks in the area of 3D printing makes it possible to offer 3D printing services for large format parts, multiple times larger than the printer, maintaining the details and the geometric precision of the part. This is possible through the work of dividing the part in 3D CAD appropriately for 3D printing, so that the final part can be precisely assembled and glued.

Some Possibilities

3D printing can be used in the manufacture of plastic parts for the most varied applications. Among them, the most perfomed by ModelWorks are:

- 3D printing of low effort mechanical parts;

- 3D printing of molds for lamination;

- 3D printing of mockups, scale models, models;

- 3D printing of complete prototypes.

Materials

The materials used by ModelWorks include:

- Acrylonitrile Butadiene Styrene (ABS)

- Lactic Polyacid (PLA)

- Tritan

- Glycol Terephthalated Polyethylene (PETG)